- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

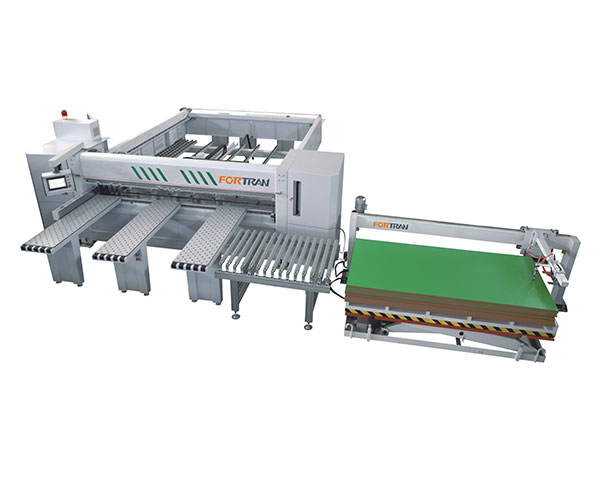

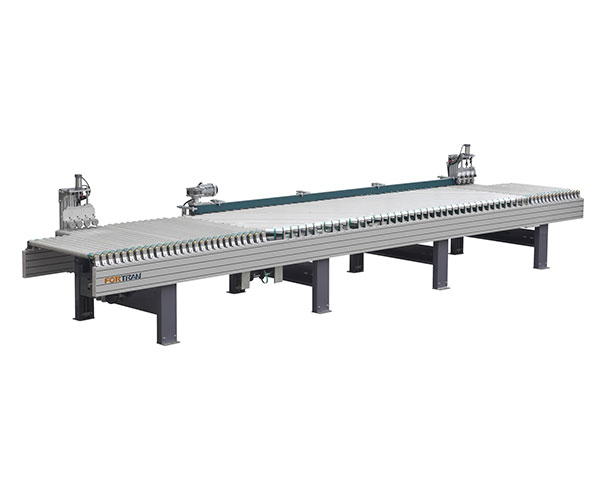

Roller Type Returning Machine for CNC Drilling Machine

Reducing the number of workers and supporting automated production is the future trend, but the automation transformation cannot be achieved in one step, and the actual situation and cost issues need to be considered. The choice of auxiliary semi-automatic products is undoubtedly a good choice. Therefore, Fortran is committed to the semi-automatic production of panel custom furniture factories and enterprises, so it has a roller type returning machine for CNC drilling machine to help enterprises reduce labor.

Send Inquiry

1.Product Introduction

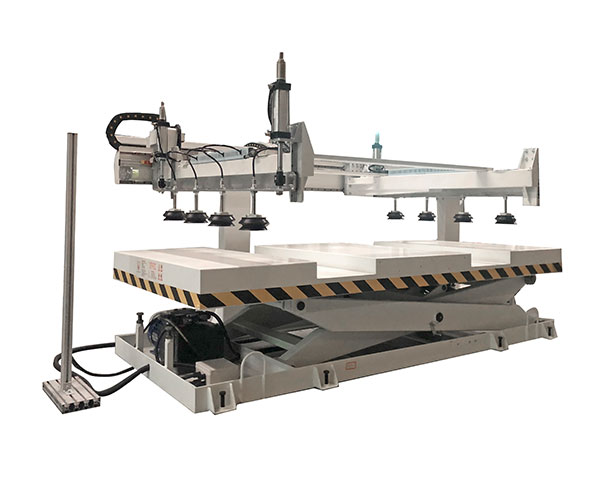

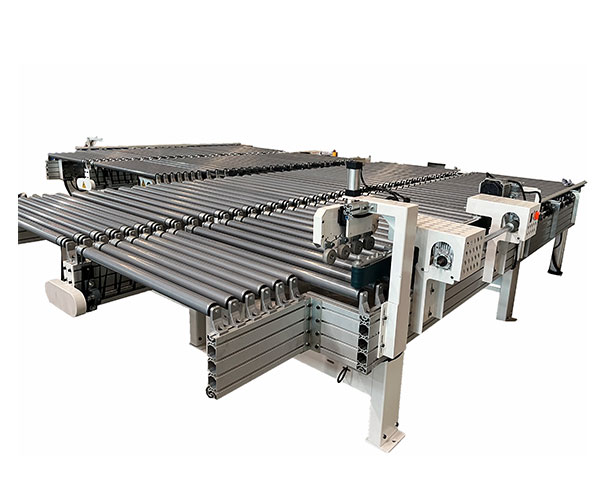

The roller type returning machine for CNC drilling machine is that after the plate is processed by six-sided drilling, there is a rear discharge platform to catch the plate, and the plate is automatically lifted to the side roller table of the operating station when conveying, so that the plate can be automatically returned to the side of the operation station. Worker operating position. Simplify the operation of six-sided drilling, change from the traditional working mode of forward and backward with 2 people to 1 person to operate, the production capacity is increased by 25%, the labor cost is saved by 50%, and the plate processing efficiency is doubled.

2. Product Parameter (Specification)

Roller Type Returning Machine for CNC Drilling Machine

| External Dimension | L4000*W1600*H950±50mm |

| Roller center distance | 120mm |

| Loading | 60kg/m² |

| Main Beam | 80*40 Aluminum |

| Roller diameter | φ54 |

| Rubber thickness | 2mm |

| Translation belt | 1600mm |

| Synchronous belt brand | Shanghai Yong Li |

| Bearing with seat | TR |

| Speed | 10-28 m/min |

| Motor | Wangxin or Zhengming |

| Frequency converter | Taiwan Delta |

| Pneumatic component | Air TAC |

| Voltage | 3 phase 380V, 50Hz |

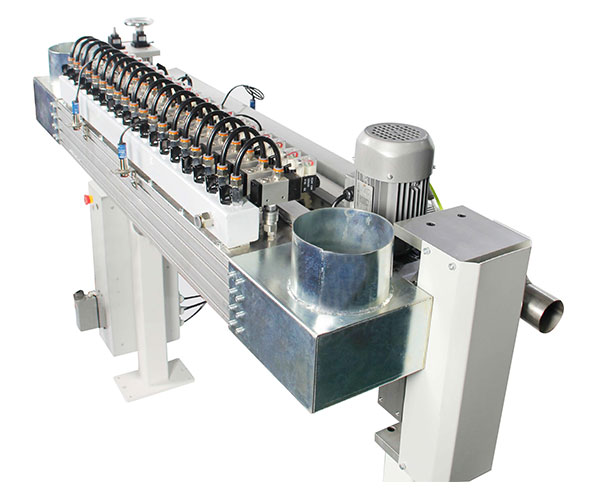

1.The roller surface is covered with imported bright silver gray rubber (wear-resistant and not vulnerable)

2.Bearing with seat: TR (genuine first-line brand, no abnormal noise, durable and not vulnerable)

3.The elastic belt is made of Shanghai Yongli, which is durable and not easy to break

4.The feet are bent integrally and welded with high strength

4.Product Details