- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

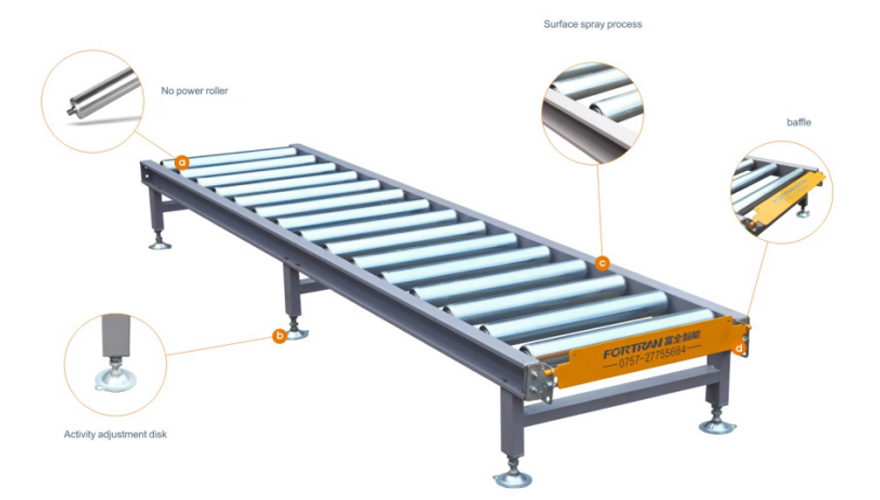

Can we improve efficiency by doing the simple work of maintaining the conveyor well?

The answer is yes. Conveyor maintenance is a systematic and simple work. Don't think it is too responsible. As the saying goes, "practice makes perfect". The longer the maintenance time is, the more experience you have. The maintenance time will definitely be shorter and shorter, and the efficiency ......

Read MoreWhat belt breakage problems often occur in belt conveyors?

In the face of today's vast market, in order to save manpower and material resources, many companies have begun to use belt conveyors. Its market demand is gradually expanding. It is the main equipment for continuous transportation of modern bulk materials. So what belt breakage problems will occur?

Read MoreWhat are the requirements for on-site installation of belt conveyors?

The belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved thereon. The roller that drives the conveyor belt to rotate is called the drive roller (transmission roller); the other roller that only changes the direction of movement of the conveyor belt is called......

Read MoreThe unpowered roller is the main conveyor accessory of the production line

Routine inspections should be carried out before starting the machine, and materials, tools, and debris should be piled on the unpowered roller conveyor. After stopping the machine, all kinds of waste residues left by the operation of the machine on that day should be cleared from each working area ......

Read More