- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

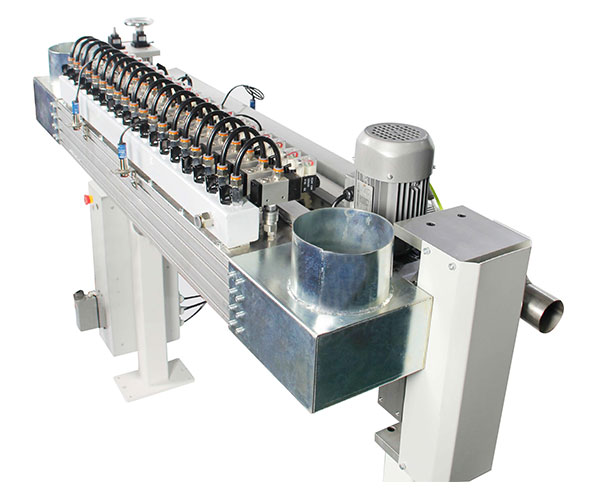

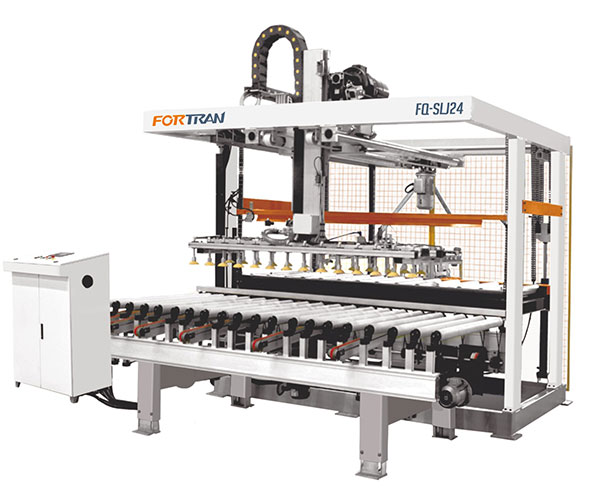

Automatic Brush Cleaning Dust Sweeper

Automatic Brush Cleaning Dust Sweeper can effectively solve the problem of large amount of dust or fiber particles caused by processing technology, such as cutting, slotting, drilling or engraving; Automatic Brush Cleaning Dust Sweeper can avoid the influence of foreign matters on the quality of the product surface and reduce the defective rate of the product caused by the foreign matters not being cleaned;

Model:FQ-QS1

Send Inquiry

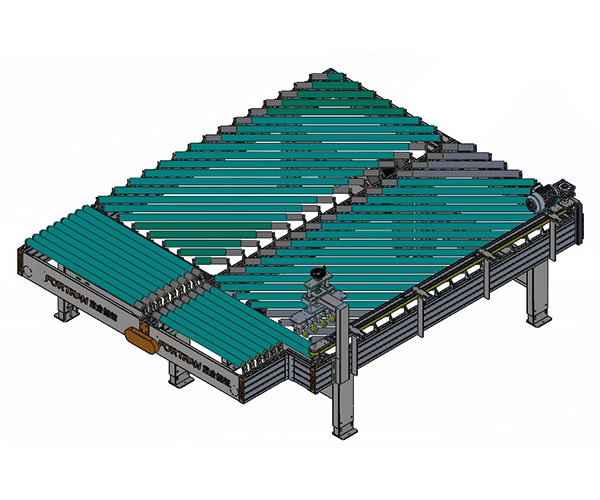

1.Product Introduction

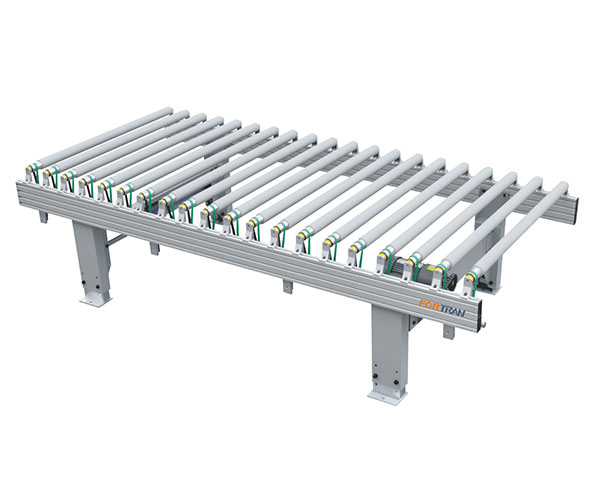

Automatic Brush Cleaning Dust Sweeper is suitable for all sections of furniture production automation line such as Edge banding section, CNC drilling section and etc. Automatic Brush Cleaning Dust Sweeper is easy to integrate and can be installed in the place required by the production line without occupying the ground space; Automatic Brush Cleaning Dust Sweeper is equipped with a brush pressing and air bag, when the sensor detects a workpiece, the air bag will automatically press down to increase the brush sweeping force which can make the cleaning more thorough;

2. Product Parameter (Specification)

| Model | FQ-QS1 |

| Appearance Size of Equipment | 2400mm |

| Diameter of suction port | 60mm*2 diameter 150*2 |

| Working width | 1450 mm |

| Transverse brushing speed | 96 m/min |

| Motor power | 0.25KW (WOSEN motor) |

| Working Pressure | 6 bar |

| Minimum pass size | 240*240mm*5mm |

| Requirements for central dust removal | 40 m/min |

| The working height of the roller conveyor | 950mm |

| Glue is not within the scope of cleaning | |

| Manual screw lifting adjustment, adjustable range 0-130 mm |

1.Patented Heavy Aluminum Material Used in the Whole Machine

2.Use wear-resisting and anti-static poly-amide brush for up to 2 years.

3.Self-made brush cleaning device to increase the adhesion of brush through micro humidifying device

4.Super stress beam with 8 silica gel wheels to prevent slab deviation

5.Random allocation of two sets of injection devices

4.Product Details