- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

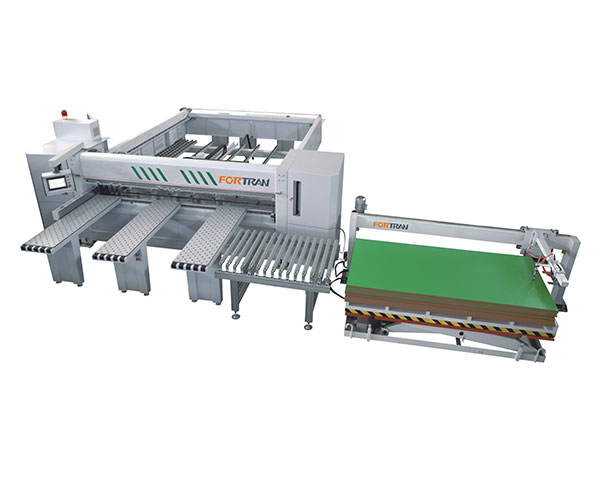

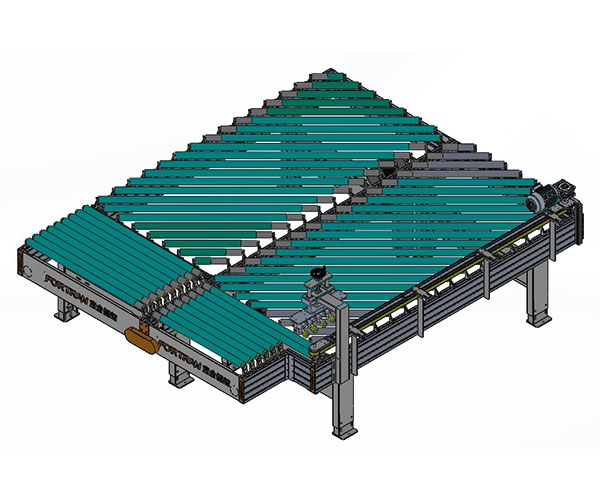

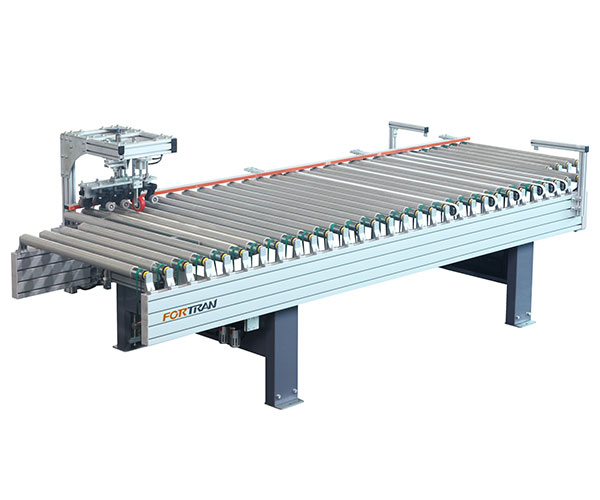

Slanting Roller Conveyor for Infeed

FORTRAN is the top leading manufacturer and supplier of automation line in China. Powered slanting roller conveyor is applicable for connection of 2 edgebanding machines, and connection of 2 double-edgebanding machines. Fortran engineer provides the best solution for your needs. The following is an introduction to Slanting Roller Conveyor for Infeed, I hope to help you better understand it.

Send Inquiry

1.Product Introduction

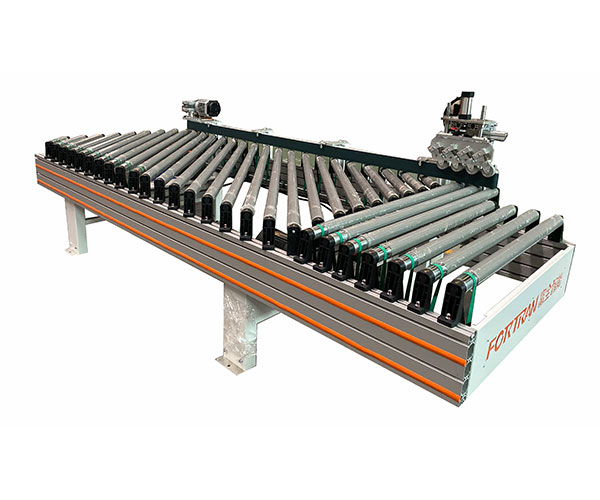

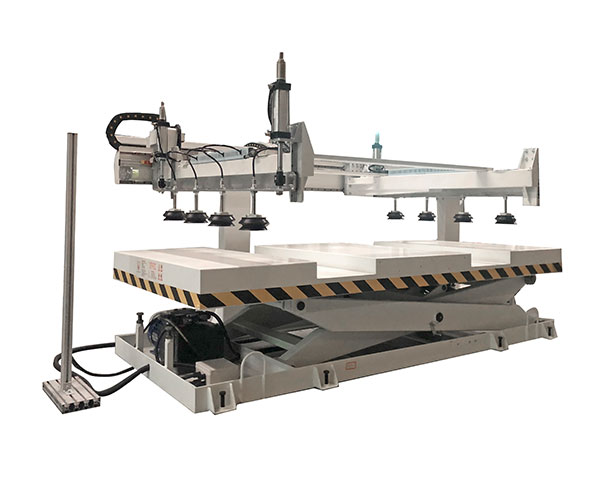

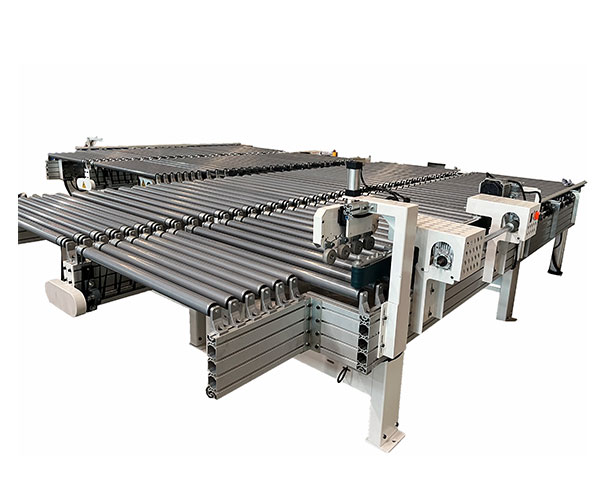

Slanting Roller Conveyor for Infeed is divided into single-row slanting roller conveyor and double-row slanting conveyor based on the panel size. Powered slanting roller conveyor can automatically separate plates with two-stage speed. For better banding panel’s edge, powered slanting roller conveyor has powered belt which provides power for panel moving on.

2. Product Parameter (Specification)

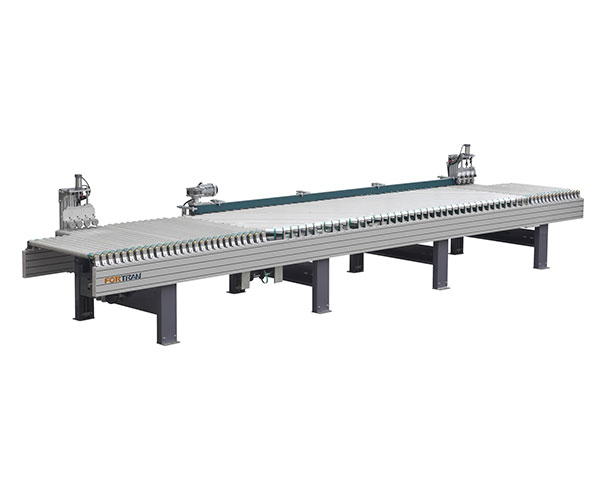

a. Single-row powered slanting roller conveyor:

| Model | FQ-XGJL1415 |

| External Dimension | L3500*W1415*H900mm |

| Panel length | 250-1200mm |

| Panel width | 250-1200mm |

| Main beam | 240*50 aluminum |

| Loading capacity | 50kg/m² |

| Roller distance | 120mm |

| Roller diameter | φ54 |

| Roller rubber thickness | 2mm |

| Total power | 0.75KW*2 + 0.55KW*1 |

| Working height | 900mm |

| Photoelectric switch | German Sick |

| Frequency converter | Delta/ Inovance |

| Electric machinery | WANSHSIN |

| Pneumatic components | Taiwan AirTAC |

| Model | FQ-XGJL2830 |

| External Dimension | L3500*W2830*H900mm |

| Panel length | 250-1200mm |

| Panel width | 250-1200mm |

| Main beam | 240*50 aluminum |

| Loading capacity | 50kg/m² |

| Roller distance | 120mm |

| Roller diameter | φ54 |

| Roller rubber thickness | 2mm |

| Total power | 0.75KW*2 + 0.55KW*1 |

| Working height | 900mm |

| Photoelectric switch | German Sick |

| Frequency converter | Delta/ Inovance |

| Electric machinery | WANSHSIN |

| Pneumatic components | Taiwan AirTAC |

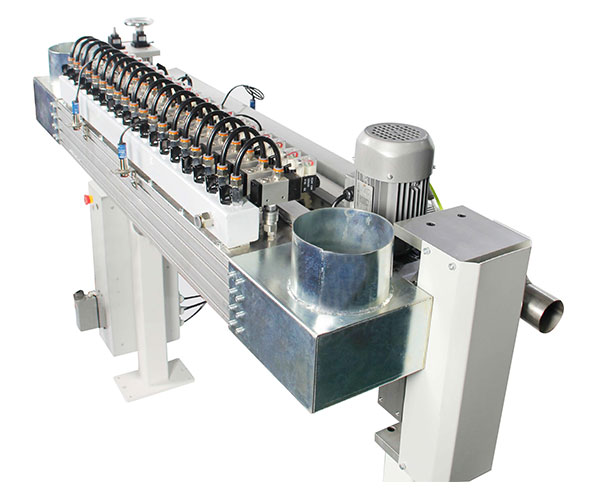

1.The main beam is made of high-strength aviation aluminum, which conforms to the international standard ICE 61131.

2.The joint part is precisely welded by Japanese OTC robot, which is corrosion-resistant and moisture-resistant for a longer service life.

3.The roller surface adopts imported bright silver gray rubber, which is wear-resistant.

4.The foot adopts the integrated bending process, which is firm and durable.

4.Product Details