- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

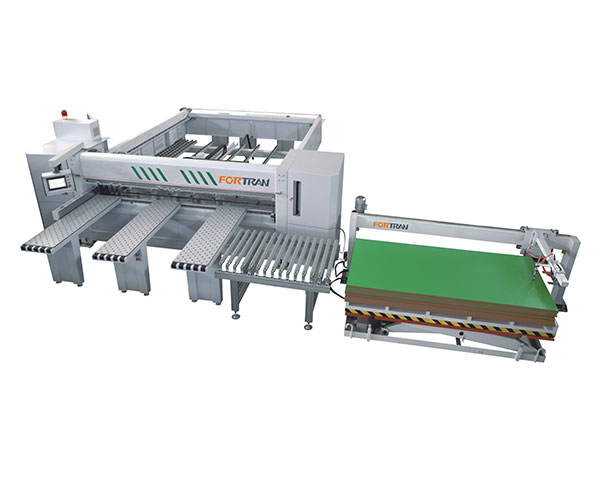

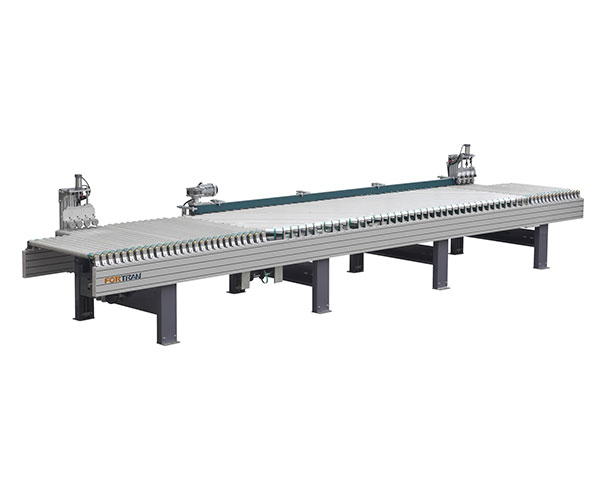

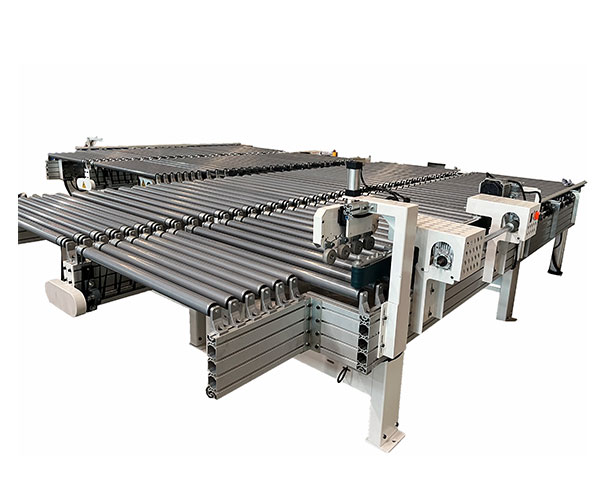

Automatic Loading and Unloading for Multi-drillng Machine

Fortran is a professional manufacturer of automatic supporting production lines. The automatic loading and unloading for multi-drillng machine of row drilling is particularly prominent. The automatic loading and unloading for multi-drillng machine of drill row is mainly applicable to the automatic connection of the whole plant, suitable for major host brands at home and abroad, and has been widely adopted by leading furniture enterprises.

Send Inquiry

1.Product Introduction

The automatic loading and unloading for multi-drillng machine of drill row can track the signal in the whole process, with high action linkage, fast speed, accurate positioning and high efficiency. Its furniture intelligent manufacturing connection saves labor and improves efficiency. Stable and rapid production, capacity upgrading and double profits. Therefore, it is widely used in customer factories. The automatic loading and unloading for multi-drillng machine of drill row can track the signal in the whole process, with high action linkage, fast speed, accurate positioning and high efficiency. Its furniture intelligent manufacturing connection saves labor and improves efficiency. Stable and rapid production, capacity upgrading and double profits. Therefore, it is widely used in customer factories.

2. Product Parameter (Specification)

Automatic Loading and Unloading for Multi-drillng Machine

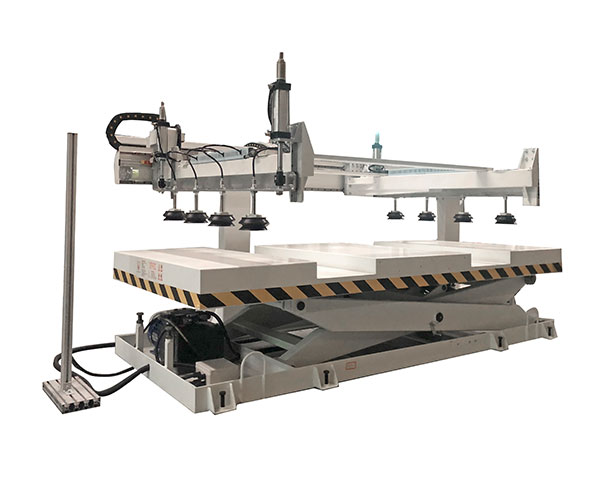

a.Four Pillar Discharger

| Model | FQ-SLJ24 |

| External Dimension | L3000*W2400*H3300mm |

| Panel length | 300-2400mm |

| Panel width | 300-800mm |

| Panel thickness | 8-60mm |

| Loading capacity for suction | 40kg/² |

| Loading capacity for table | 1500kg |

| Maximum height of panel | 1300mm |

| Total power | 6.75KW |

| Speed | 8-12 times/min |

| Roller diameter | φ89 |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

| Guide rail | Hiwin |

| Model | FQ-HFBJ24 |

| External Dimension | L3500*W1415*H1300mm |

| Panel length | 400-2400mm |

| Panel width | 300-1200mm |

| Panel thickness | 10-60mm |

| Loading capacity | 50kg/m² |

| Total power | 3KW |

| Speed | 4-5 times/min |

| Working height | 900mm |

| Translation belt | Shanghai Yongli |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

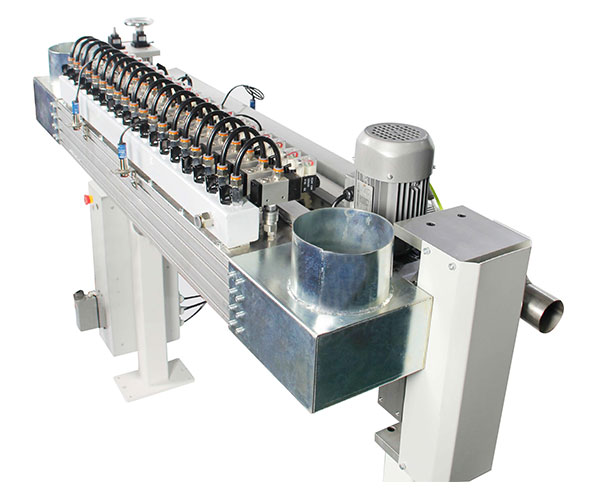

| External Dimension | L3000*W1530*H900mm |

| Panel length | 250-2400mm |

| Panel width | 250-1200mm |

| Main beam | 240*50 aluminum |

| Loading capacity | 100kg/m² |

| Roller distance | 120mm |

| Roller diameter | φ54 |

| Roller rubber thickness | 2mm |

| Total power | 0.75KW*2 |

| Speed | 10-28m/min |

| Synchronous belt | Shanghai Yongli |

| 8 synchronous belts (Roller distance is 120mm when there is a synchronous belt.) | |

| Working height | 900mm |

| Photoelectric switch | German Sick |

| Frequency converter | Delta/ Inovance |

| Electric machinery | WANSHSIN |

| Pneumatic components | Taiwan AirTAC |

3. Product Feature And Application

1.The roller surface is covered with imported bright silver gray rubber (wear-resistant and not vulnerable)

2.Bearing with seat: TR (genuine first-line brand, no abnormal noise, durable and not vulnerable)

3.The elastic belt is made of Shanghai Yongli, which is durable and not easy to break

4.The feet are bent integrally and welded with high strength

5.Taiwan Delta servo motor, controlling the vacuum cup up or down, with smooth horizontal movement.

4.Product Details